Understanding Bowling Parts for AMF

As an integral component of the bowling industry, the availability and quality of bowling parts for AMF play a significant role in maintaining the efficiency and performance of bowling centers. Over the years, Shenzhen Eternity Technology Co., Ltd. has established itself as a leading supplier of AMF spare parts, offering a diverse range of products that cater to both the operational needs of bowling alleys and the competitive requirements of bowlers. This article will delve into the various types of bowling parts available, their significance in performance enhancement, and best practices for maintenance and installation.

The Importance of Quality Parts

The performance of bowling equipment hinges on the quality of its components. Quality parts ensure seamless operation, reduce downtime, and enhance the overall bowling experience. For bowling centers, investing in high-quality AMF parts not only improves reliability but also provides a competitive edge by ensuring the highest level of service for patrons. Using inferior or counterfeit components can lead to frequent malfunctions, increased operational costs, and dissatisfied customers.

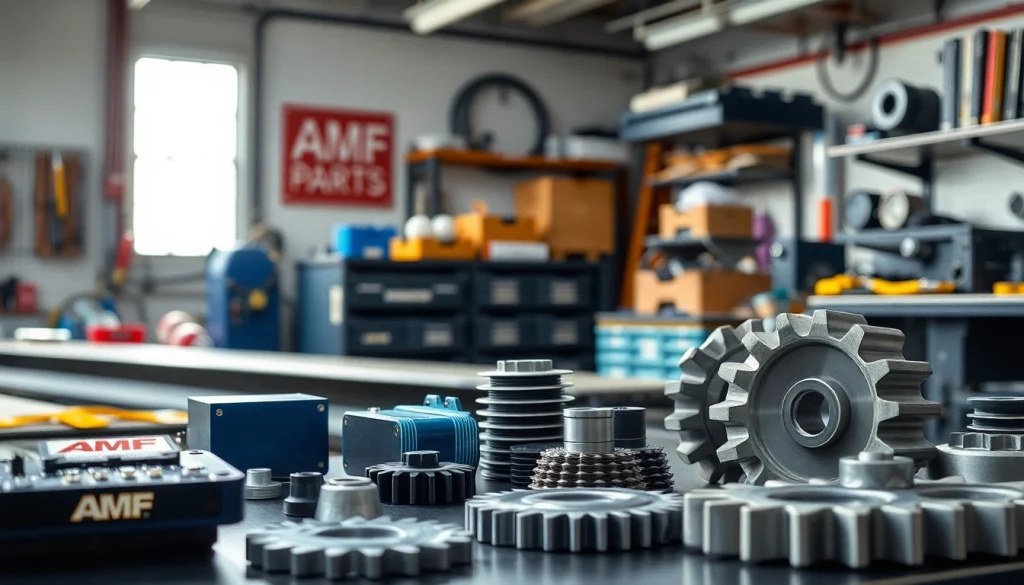

Types of AMF Bowling Parts Available

AMF bowling parts encompass a wide variety of components essential for the smooth functioning of bowling machinery. Key categories include:

- Electronic Components: Advanced electronic parts control scoring systems and lane functionality, ensuring accuracy and responsiveness.

- Machine Parts: Components such as pinsetters, ball returns, and lane coverings must be durable to withstand high-intensity use.

- Consumables: Regularly replaced items like bowling pins, lane oil, and cleaning supplies are critical for maintaining equipment performance.

- Maintenance Kits: Comprehensive kits that include various parts for routine maintenance can help extend the lifespan of bowling machines.

How AMF Parts Enhance Bowling Performance

High-quality AMF parts are specifically designed to optimize the performance of bowling alleys. Electronic components leverage technology to offer precise scoring and lane adjustments, enhancing the player experience. Meanwhile, durable machine parts can handle high traffic and rigorous use, minimizing maintenance needs and preventing disruptions during peak hours. Ultimately, these enhancements contribute to a smooth, enjoyable experience for both casual and competitive bowlers.

Identifying Genuine Bowling Parts for AMF

With a range of options available, it is crucial to distinguish between genuine AMF parts and aftermarket alternatives. Understanding these differences can save bowling operators time and resources while ensuring the optimal performance of their equipment.

Recognizing OEM vs Aftermarket Parts

Original Equipment Manufacturer (OEM) parts are designed and manufactured to meet specific standards set by AMF, while aftermarket parts may vary in quality and compatibility. Although aftermarket parts may seem cost-effective, they often lack the reliability and performance standards associated with OEM components.

Key Features of Authentic AMF Parts

Genuine AMF parts are recognized for their superior quality and reliability. Key features include:

- Durability under extreme operating conditions.

- Compatibility with existing equipment, ensuring minimal performance disruption.

- Comprehensive warranties that cover defects and offer peace of mind.

Benefits of Using Genuine Parts

Investing in authentic AMF parts leads to long-term savings and operational efficiency. Benefits include:

- Increased Reliability: Genuine parts are tested to conform to high-quality standards, reducing the likelihood of breakdowns.

- Enhanced Safety: Components designed specifically for AMF equipment help mitigate risks associated with faulty parts.

- Support for Ongoing Innovation: Using OEM components guarantees ongoing compatibility with new technology updates and improvements.

Challenges in Sourcing AMF Bowling Parts

While sourcing AMF bowling parts, operators often face challenges that can complicate maintenance and repairs. Understanding these challenges helps in developing effective strategies.

Common Misconceptions About AMF Parts

A prevalent misconception is that all parts labeled as compatible with AMF are of equal quality. This can lead to operators choosing inferior products that may not perform well or last as long as expected.

Supply Chain Issues and Solutions

Global supply chain challenges can affect the availability of parts. To mitigate these issues, bowling centers should establish relationships with reliable suppliers, understand their inventory capabilities, and consider placing orders in advance to ensure essential parts are always available.

How to Choose Reliable Suppliers

Choosing the right supplier for AMF parts is critical. Operators should consider:

- Supplier reputation and customer reviews.

- The range and quality of parts offered.

- Delivery times and reliability.

- After-sales support and service capabilities.

Installation and Maintenance of AMF Parts

Proper installation and ongoing maintenance of bowling parts are essential for longevity and performance. Operators should adhere to best practices to ensure optimal machine functioning.

Step-by-Step Installation Guide

Installing AMF parts typically involves the following steps:

- Preparation: Gather necessary tools and components.

- Removal: Carefully disassemble the old parts, taking care to note configurations.

- Installation: Follow the manufacturer’s guidelines to install the new parts correctly.

- Testing: Conduct a test run to ensure everything is functioning as intended.

Best Practices for Maintenance

Ongoing maintenance routines should include regular inspections, cleaning, and lubrication of moving parts. Operators can also benefit from keeping a log of maintenance activities to track issues and ensure timely servicing.

Cost-Effective Repair Techniques

For cost-effective repairs, centers should consider:

- Performing regular preventative maintenance to reduce the need for extensive repairs.

- Utilizing compatible aftermarket components when necessary and ensuring they meet quality standards.

- Training staff to handle minor repairs to minimize downtime.

Future Trends in Bowling Parts for AMF (2025 and Beyond)

The bowling industry is poised for transformation as new technologies emerge and customer preferences evolve. Staying informed about these trends is crucial for bowling center operators.

Evolving Technologies in Bowling Equipment

The incorporation of smart technology into bowling equipment is on the rise. Features like automated scoring, lane condition monitoring, and player performance analytics are becoming standard, necessitating compatible parts that can integrate with these systems.

Impact of Innovations on Bowling Parts

Innovations in materials science and engineering are leading to the development of lighter, more durable bowling components. These advancements not only improve performance but also reduce overall maintenance costs.

Preparing for Future Needs in Bowling Parts

Bowling centers should proactively assess their needs and adapt their inventories accordingly. Engaging with suppliers for insights on upcoming product developments will ensure they remain competitive in the evolving landscape.